FIT diversifies and enters the plant protein sector

19 November 2021

Faced with the increasing population and a certain awareness of changes to be made, industrialists and consumers have moved towards […]

More informations

19 November 2021

Faced with the increasing population and a certain awareness of changes to be made, industrialists and consumers have moved towards […]

More informations

19 November 2021

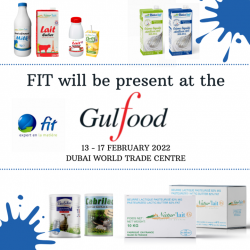

Lacticare will be present at the next edition of Gulfood from 13 to 17 February 2022 GULFOOD is one of […]

More informations

19 November 2021

Discover LACTICARE, the powdered and baby milk sector of the FIT company In 2019, FIT took over the “baby powders […]

More informations